Bud Nail recently got in touch to tell us about his environmentally friendly digital display project in LiveCode, a fascinating project that Bud is trying to raise funds for on KickStarter. He has kindly agreed to do a guest blog post to tell us all about the project…

First, just a little bit of background on FlipBit. You can go deeper by visiting our KickStarter page at http://tinyurl.com/flipbit. Recently, I was looking for a project that would keep my intern, Alex, interested as he learns to use design and fabrication tools. I had been mentally designing what might be called a mechanical pixel for many years. Typically, it would come to mind when on a long boring drive with nothing much to look at but trees and roadside signs. I had mentally tested and rejected many approaches for cost and complexity reasons, but at some point I finally focused in on what I thought was probably an optimum design. Alex became my inspiration to finally get the design out of the gray matter and into something tangible.

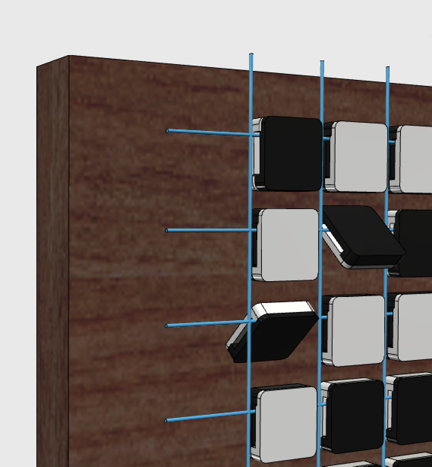

Figure 1 – 3D illustration of FlipBits

As we went through the 3D design, build and testing process, we quickly realized we had a chicken and egg type problem. We needed lots of FlipBits to test our ideas. To fund making lots of FlipBits we needed to demonstrate some practical uses. To demonstrate some practical uses, we needed not only a lot of FlipBits but structures to support them. We needed a way to “KickStart” the manufacturing of FlipBit technology.

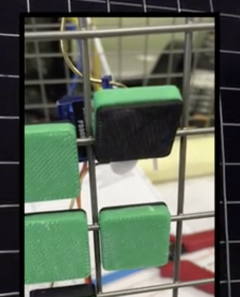

We made a video and were able to show several 3D printed FlipBits, doing what they do – flipping. But we didn’t have enough FlipBits to display even a single character, much less a whole word or wall of FlipBits. My son with production credits in a number of films, TV shows and commercials, said after reviewing the video “I kept waiting for the big payoff where you show a big wall of FlipBits or something.”

Figure 2 – 3D Printed FlipBits in Action

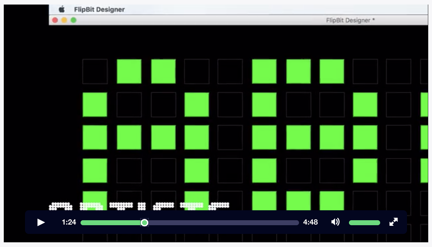

This is where LiveCode came to the rescue. In about an hour I created the first version of FlipBit Designer, a design tool and simulator of FlipBit based products. I made an array of buttons, each simulating a single FlipBit. Now, not only could we show a number of “working FlipBits”, but also we had the beginnings of a KickStarter reward that we can ship to the world at no cost.

Figure 3 – FlipBit Designer Shown in KickStarter Video

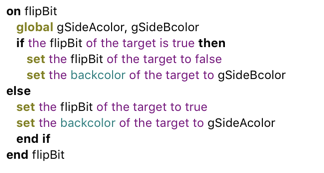

FlipBit, being an open design technology, it is important that we be able to explain what we are doing. We want people to understand and build upon our designs. LiveCode’s English-like syntax makes it possible for even non-coders to follow the logic. By using one LiveCode object to represent one real world object, a FlipBit, it makes explaining code structure much easier to people who may have never thought about software design before. Because LiveCode can take our code and produce Apps for a variety of platforms like Windows, Mac, Linux, and even mobile devices, our open design can appeal to wider audience.

Figure 4 – FlipBit Designer Code Shown in KickStarter Update

To build a large physical wall of FlipBits, we have to scale up manufacturing, but what about FlipBit Designer? Would the one LiveCode FlipBit object equals one physical FlipBit design scale? I asked this question on the LiveCode Users Group on Facebook and the responses were helpful, but in the end we just had to test and see. So I added input fields to enter horizontal and vertical dimensions, and a script to create an array of virtual FlipBits based on the entries. The results: Over ten thousand (10,500) FlipBits per LiveCode card object resulted in no discernible delay when interacting with the FlipBits. Not only do the thousands of simulated FlipBits do what FlipBits do (Flip) they also display their coordinate locations when the mouse hovers over them using the LiveCode tooltip feature.

Figure 5 – FlipBit Designer Simulating 10,500 FlipBits

Since the KickStarter project launched, we have continued to improve FlipBit Designer to include such features as slicing and dicing photos and attaching the parts to individual FlipBits. Some people didn’t really relate to the project until we demonstrated how to flip an old 3-cent nickel. (You’ll have to go to the project to check that out.) It was LiveCode’s outstanding ability to manipulate images that made this possible. We are excited about some other features we will be bringing to FlipBit Designer that will allow users to virtually build, demonstrate and even sell their personal FlipBit designs, before spending a dime on physical hardware. If you are a “maker” type person, a coder interested in obtaining the complete code for the project months ahead of the rest of the world, or just want to encourage us, please visit the our project page and consider becoming a project backer.

Bud Nail

Vice President of Operations

Technological Services Company

8 comments

Join the conversationMatthias Rebbe - August 16, 2016

Really interesting, but the pledges are only sent to the US. It´s a pity, that there is no “code only pledge”.

Bud Nail - August 16, 2016

Matthias, You are right. Thanks for pointing that out. I’ll add that. Plus it will include files and instructions for 3D printing or constructing your own flipbits. We’ll call it something like “the software only option.”

Matthias Rebbe - August 16, 2016

oh, that´s great.

Louis - August 16, 2016

That is pretty cool. Wonder how big that can scale?

Bud Nail - August 16, 2016

That is a good question, and one we hope answer with this project(in terms of great numbers of FlipBits). Hopefully, we won’t reach the upper limit, but show that it will scale beyond what most applications would require. As far as the physical size of a single FlipBit, our experiments show that 10mm is about the smallest that works well via 3D printing. As they get orders of magnitude larger we expect to run into some materials and structural challenges.

Richmond Mathewson - August 16, 2016

This reminds me of a thing we had at my experimental Primary school in about 1968: the only difference being that the “bits” were round rather than square.

Bud Nail - August 16, 2016

One of our first backers that I didn’t know personally, said he had the same ideas years ago, but never did anything with it. The slot design part – I have trouble believing someone hadn’t built before. The version we actuate magnetically (we haven’t really disclosed how that works yet) is pretty magical, and frankly we didn’t expect it to work as well as it does. That part plus the thoughts and experiments we have put into how you actually make these things inexpensively is probably where we are bringing the most value.

Kamagra - August 8, 2017

To build a large physical wall of FlipBits, we have to scale up manufacturing, but what about FlipBit Designer? Would the one LiveCode FlipBit object equals one physical FlipBit design scale